|

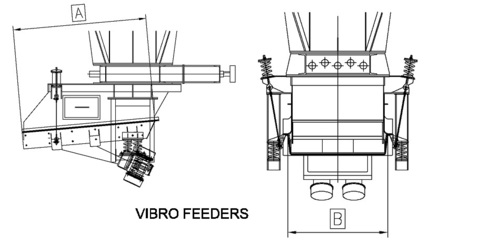

Polyurethane Vibro Feeders

Polyurethane Vibro Feeders Specification

- Classification

- Industrial Component

- Type

- Vibratory Feeder

- Grade

- Premium

- Purity

- High

- Application

- Material Handling, Controlled Feeding, Manufacturing Automation

- Color

- Yellow

- Form

- Solid

- Size

- Customizable

- Material

- Polyurethane

- Frequency

- 50 Hz/60 Hz

- Mounting Type

- Base Mounted

- Operating Voltage

- 220V/440V

- Feed Capacity

- Adaptable as per requirement

- Operating Temperature Range

- -20°C to +80°C

- Maintenance

- Minimal, easy to clean surface

- Service Life

- Extended due to abrasion resistance

- Corrosion Resistance

- Excellent

- Surface Finish

- Smooth

- Noise Level

- Low

- Design

- Anti-spill and vibration dampening

- Wear Resistance

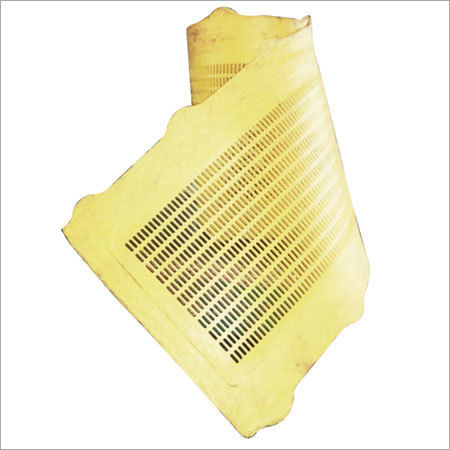

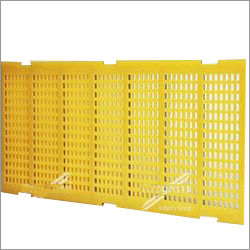

- High, due to polyurethane lining

Polyurethane Vibro Feeders Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Polyurethane Vibro Feeders

We are counted amongst as the foremost manufacturers and suppliers of superior quality range of Polyurethane Vibro Feeders which are fabricated using premium grade polyurethane. The offered feeders are widely used in mechanical and automobile industries to remove the problem of vibration during welding. Manufactured under the proper supervision of our deft experts, these feeders are known for their sturdy construction. Moreover, these Polyurethane Vibro Feeders can be availed from us at in various shapes and sizes at industry leading prices.

Features:

- Robust construction

- Durability

- Easy to install

- High strength

Superior Material Handling with Polyurethane Vibro Feeders

Experience precise and controlled feeding in your industrial processes using our polyurethane vibro feeders. Their high purity and premium-grade construction provide unmatched durability and performance. Designed for consistent material flow and minimal maintenance, these feeders integrate seamlessly into manufacturing automation and bulk material handling lines, delivering reliable operation in demanding environments. Their base-mounted structure allows flexible placement, while the abrasion and corrosion-resistant polyurethane lining ensures exceptional longevity. Ideal for manufacturers seeking efficiency and quality.

Engineered for Reliability and Efficiency

Our vibro feeders feature a vibration-dampening system and anti-spill design, which together guarantee smooth, quiet operation and enhanced safety. With the adaptable feed capacity and customizable sizing options, these feeders can be tailored to specific application needs. The smooth, easy-to-clean surfaces reduce maintenance downtime, while the extended service life means less frequent replacements, maximizing productivity and minimizing total cost of ownership for industrial operations.

FAQs of Polyurethane Vibro Feeders:

Q: How do polyurethane vibro feeders improve material handling processes?

A: Polyurethane vibro feeders provide precise, consistent, and controlled feeding of materials, reducing spillage and product waste. Their vibration-dampening design ensures stable operation, optimizing efficiency in handling bulk materials during manufacturing and automation processes.Q: What are the main benefits of using polyurethane lining in these feeders?

A: The polyurethane lining offers superior wear resistance and outstanding corrosion protection, significantly extending the feeders service life. It also ensures a low-friction surface, which aids in reducing maintenance needs and facilitates easy cleaning.Q: Where can these vibro feeders be installed?

A: These feeders are base-mounted, allowing installation on various industrial floors or machinery bases. They can be integrated into existing material handling systems or new setups in factories, warehouses, and manufacturing plants.Q: When should I consider using a polyurethane vibro feeder?

A: A polyurethane vibro feeder is ideal when you require controlled feeding, minimal maintenance, and high resistance to wear and corrosion, especially in demanding industrial settings such as material handling, manufacturing automation, and process industries.Q: What is the operating voltage and frequency range of these feeders?

A: The feeders operate on 220V or 440V electrical supply and are compatible with both 50 Hz and 60 Hz frequencies, making them suitable for diverse industrial power standards.Q: How simple is the maintenance process for these feeders?

A: Maintenance is minimal due to the smooth, non-stick polyurethane surface. Routine cleaning and inspection are straightforward, and the durable-polyurethane construction reduces the frequency of repairs or replacements.Q: What makes these feeders a premium choice for industrial applications?

A: Their premium grade, high purity polyurethane material, extended service life, corrosion/abrasion resistance, and customizable feed capacity collectively ensure reliable, efficient, and long-lasting performance, meeting the rigorous demands of industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

Polyurethane Liners

Minimum Order Quantity : 1 Piece

Form : Other, Sheet / Plate / Liner

Grade : Industrial Grade

Size : Customizable, Standard thickness ranges typically from 2mm to 100mm

Type : Other, Polyurethane Liners

Polyurethane Wiper Blades

Price Range 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Form : Other, Blade

Grade : Industrial Grade

Size : 18 to 26 (custom sizes available)

Type : Other, Wiper Blade

Polyurethane Hydrocyclone

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Form : Other, Cylindrical/Conical

Grade : Industrial Grade

Size : Customizable size as per application

Type : Other, Hydrocyclone Separator

Cast Polyurethane Products

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Form : Other, Sheet, Rod, Custom Molded

Grade : Other, Industrial

Size : Custom sizes available

Type : Other, Cast Polyurethane

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry