|

Polyurethane Gear Couplings

Polyurethane Gear Couplings Specification

- Classification

- Polyurethane Gear Coupling

- Type

- Flexible Coupling

- Grade

- Industrial Grade

- Purity

- High

- Application

- Mechanical Power Transmission

- Color

- Yellow

- Form

- Solid

- Material

- Polyurethane & Steel

- Size

- Customized sizes available

Polyurethane Gear Couplings Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Polyurethane Gear Couplings

Polyurethane Gear Couplings

As an eminent enterprise, we manufacture and supply an exclusive range of Polyurethane Gear Couplings. Manufactured by utilizing premium quality raw materials and the leading edge technology as per the latest market trends, the offered couplings are also tested on several quality parameters. Our provided couplings are mainly utilized in automobile, electrical and other industries in order to shift power between two shafts. Moreover, these Polyurethane Gear Couplings are available in different specifications to fulfill the varied needs of the clients.

Products Features:

- Durability

- Anti-corrosive

- Optimum strength

- Robust construction

Exceptional Flexibility and Damping

These gear couplings feature polyurethane elements providing superior flexibility, vibration absorption, and damping properties. This ensures smoother power transmission, a key advantage in reducing equipment stress and extending operational life in heavy-duty mechanical assemblies.

Durability in Extreme Conditions

With a hardness of Shore A 90 5, temperature resistance from -40C to +80C, and impressive wear resistance, this product is ideal for industrial settings exposed to harsh operational stresses. The solid polyurethane and steel construction guarantees longevity with minimal maintenance requirements.

Customizable for Diverse Applications

Manufacturers in India offer customized sizing to meet specific needs, suitable for various OEM projects. Flange or hub mounting options and a flexible connection allow integration into a wide range of mechanical power transmission systems, enhancing both performance and reliability.

FAQs of Polyurethane Gear Couplings:

Q: How does the polyurethane material benefit gear couplings in industrial applications?

A: Polyurethane delivers high flexibility and excellent vibration absorption, which helps reduce wear and tear on connected machinery. Its strong damping characteristics minimize stress and prolong the couplings lifespan, making it ideal for heavy-duty usage.Q: What is the process for replacing the polyurethane insert in these gear couplings?

A: The insert can be easily replaced without disassembling the entire coupling. Simply unmount the flange or hub, remove the worn insert, and fit the new one, ensuring quick maintenance and minimal downtime.Q: When should a Polyurethane Gear Coupling be used over traditional couplings?

A: It is recommended for setups that require superior torque transmission, flexibility, and vibration absorptionespecially where equipment is subject to misalignment or harsh operational conditions.Q: Where are these couplings most commonly applied?

A: They are widely used in mechanical power transmission for industrial machinery, conveyor systems, pumps, and other rotating equipment requiring reliable and flexible connections under varying loads.Q: What is the maximum operational speed and torque capacity of these couplings?

A: Depending on model and size, the couplings handle speeds up to 3,500 RPM and provide torque transmission capacities up to 25,000 Nm, accommodating heavy industrial requirements.Q: How does the use of flange or hub mountings affect installation?

A: Both mounting types offer robust attachment methods, allowing the coupling to be securely fixed to the shaft ends. This ensures stable operation, easy alignment, and swift servicing during insert replacements.Q: What are the long-term benefits of using Polyurethane Gear Couplings?

A: Users gain reduced maintenance requirements, easy insert replacement, outstanding wear resistance, and extended service life. This minimizes operational costs and improves reliability in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

Cast Polyurethane Products

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Classification : Other, Polyurethane Elastomer

Color : Yellow

Application : Other, Engineering, Mining, Automotive, Material Handling, Rollers, Linings, Seals

Size : Custom sizes available

Polyurethane Suspension Bush

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Classification : Other, Polyurethane Suspension Bush

Color : Yellow

Application : Other, Automotive Suspension, Vibration Damping

Size : Customizable

Polyurethane Star Coupling

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Classification : Other, Mechanical Coupling

Color : Other, Red, Yellow, Green

Application : Other, Mechanical Power Transmission, Flexible Coupling for Motors and Pumps

Size : Customizable, Range Available

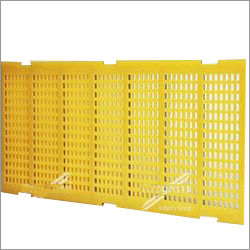

Polyurethane Dewatering Screen

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Classification : Other, Dewatering Screen

Color : Yellow

Application : Other, Mining, Sand & Gravel Aggregate Dewatering

Size : Customized sizes available

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry