|

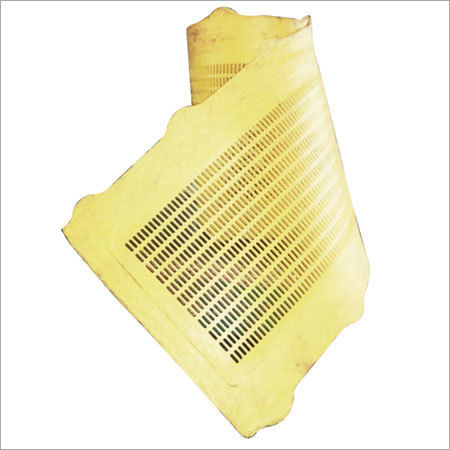

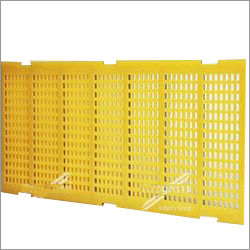

Polyurethane Dewatering Screen

Polyurethane Dewatering Screen Specification

- Classification

- Dewatering Screen

- Grade

- Industrial Grade

- Application

- Mining, Sand & Gravel Aggregate Dewatering

- Color

- Yellow

- Form

- Screen Panel

- Material

- Polyurethane

- Size

- Customized sizes available

- Usage

- Vibrating Screen Machine

- Hardness

- 70-95 Shore A

- Tensile Strength

- High tensile and tear resistance

- Mounting Type

- Bolt-on/Clamp-on

- Lifespan

- Long service life compared to traditional screens

- Operating Temperature

- -40 to 80°C

- Feature

- High screening efficiency, wear resistance, corrosion resistance

- Thickness

- 10 mm to 60 mm or as per requirements

- Mesh Size

- Available in various mesh openings

Polyurethane Dewatering Screen Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Polyurethane Dewatering Screen

We have marked a remarkable position in the industry by manufacturing and supplying a wide spectrum of Polyurethane Dewatering Screen. With the aid of modern techniques under our professionals' guidance, it is efficiently manufactured by utilizing optimal quality polyurethane. This screen finds its main use in building rubble, wood chips, plastic etc in the making of consistent drip-free product. In addition to this, the offered Polyurethane Dewatering Screen is available to the clients at affordable prices.

Products Features of Polyurethane Dewatering Screen:

- Robust built

- Optimum finish

- Highly durable

- Excellent strength

FAQs of Polyurethane Dewatering Screen:

Q: How does the polyurethane dewatering screen improve efficiency in vibrating screen machines?

A: The polyurethane dewatering screen is engineered with high screening efficiency, reducing water content and increasing throughput. Its superior wear and corrosion resistance ensures consistent performance over extended periods, maximizing operational productivity.Q: What customization options are available for mesh size and thickness?

A: Customers can select mesh openings and panel thicknesses according to project specifications, ranging from 10 mm to 60 mm or as required. This flexibility allows the screens to be tailored for varying material types and dewatering needs.Q: When should I choose polyurethane screens over traditional metal screens?

A: Polyurethane screens are recommended when applications demand high tensile strength, superior tear resistance, and corrosion protectione specially in aggressive environments such as mining and aggregate dewatering resulting in longer service life compared to conventional screens.Q: Where are these dewatering screens commonly used?

A: These screens are widely utilized in mining operations, sand and gravel aggregate dewatering plants, and similar industrial settings that require reliable separation and moisture reduction in processed materials.Q: What process is used to mount the screen panels onto vibrating machines?

A: Polyurethane dewatering screens are designed for bolt-on or clamp-on mounting, enabling quick and secure installation onto vibrating screen frames. This ensures minimal downtime and easy panel replacement during maintenance.Q: How does the screen panels operating temperature range benefit industrial applications?

A: With an operating temperature span from -40C to 80C, the screen panels perform reliably in both cold and hot environments, maintaining their structural integrity and screening efficiency under extreme conditions.Q: What are the main advantages of using industrial-grade polyurethane screen panels?

A: The primary benefits include extended lifespan, reduced maintenance, high efficiency, and resistance to wear, tear, and corrosion. These qualities translate into lower operating costs and consistent performance for demanding dewatering tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

Polyurethane Hydrocyclone

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Form : Other, Cylindrical/Conical

Grade : Industrial Grade

Material : Polyurethane

Polyurethane Gear Couplings

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Form : Solid

Grade : Industrial Grade

Material : Polyurethane & Steel

Conveyors Rollers

Minimum Order Quantity : 1 Piece

Color : Multicolored

Form : Solid

Grade : Industrial Grade

Material : PU

PU Tiles

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Multicolored

Form : Solid

Grade : Industrial Grade

Material : PU

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry