|

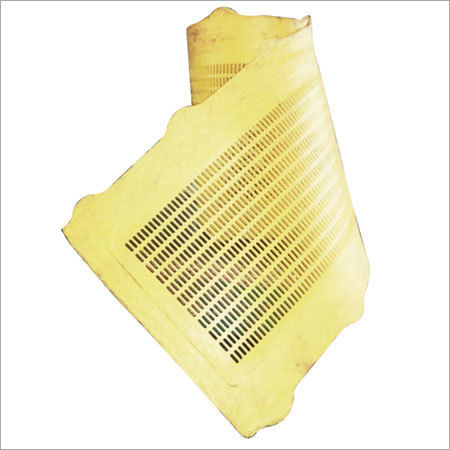

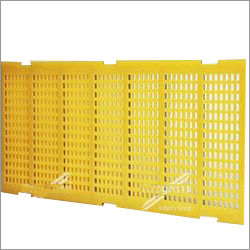

Polyurethane Liners

Price 1000 INR/ Piece

Polyurethane Liners Specification

- Classification

- Polymers

- Type

- Polyurethane Liners

- CAS No

- 9009-54-5

- EINECS No

- 618-466-4

- Grade

- Industrial Grade

- Purity

- 99%

- Application

- Wear Resistance, Abrasion Protection, Material Handling, Mining Industry, Chute Lining, Hopper Lining, Conveyor Systems

- Color

- Red

- Form

- Sheet / Plate / Liner

- Size

- Customizable, Standard thickness ranges typically from 2mm to 100mm

- Material

- Polyurethane

- Elongation at Break

- 300% - 600%

- Surface Finish

- Smooth

- Density

- 1.12 - 1.25 g/cm³

- Feature

- Corrosion Resistant, Non-Stick, Long Service Life

- Tensile Strength

- 31-50 MPa

- Water Absorption

- Low

- Installation Method

- Adhesive or Mechanical Fastening

- Impact Resistance

- High

- Thickness Range

- 2 mm to 100 mm

- Temperature Resistance

- -30°C to +80°C

- Hardness

- 60-95 Shore A

Polyurethane Liners Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Polyurethane Liners

Our enterprise has gained immense recognition in manufacturing and supplying a quality assured assortment of Polyurethane Liners. These liners are manufactured with high precision by utilizing the finest grade polyurethane with the help of modern techniques under our professionals observation. The provided liners are mainly used in building rubble, wood chips, plastic etc to secure edges. Furthermore, these Polyurethane Liners can be availed by the customers at a very reasonable rate.

Features:

- Rugged design

- High tensile strength

- Accurate dimension

- Crack resistance

Exceptional Durability & Protection

Designed for demanding applications, polyurethane liners safeguard equipment from wear, abrasion, and mechanical impact. Their high elongation and tensile strength values allow for flexibility and robust performance, even in extreme environments. They significantly prolong the service life of chutes, hoppers, and conveyor components.

Versatile Applications in Industry

These liners excel in a range of industries, including mining, material handling, and bulk transport. Suitable for use as chute, hopper, and conveyor linings, their corrosion resistance and low water absorption ensure minimal maintenance and reliability in both wet and dry conditions.

Simple Installation & Custom Solutions

Polyurethane liners can be installed quickly using adhesive bonding or mechanical fastening methods. Their customizable sizes and forms (sheet, plate, liner) ensure a tailored fit for every unique operational requirement, optimizing equipment performance and reducing downtime.

FAQs of Polyurethane Liners:

Q: How are polyurethane liners installed?

A: These liners are typically installed using adhesive bonding or mechanical fastening methods, depending on the application and surface requirements. Selection of the technique ensures a secure and long-lasting fit.Q: What benefits do polyurethane liners offer over traditional materials?

A: Polyurethane liners provide superior abrasion and impact resistance, non-stick surface properties, and exceptional temperature and corrosion resistance, resulting in a longer service life compared to conventional lining materials.Q: Where can polyurethane liners be used in industrial settings?

A: Common applications include chute lining, hopper lining, conveyor systems, mining operations, and material handling equipment, where abrasion protection and reduced material buildup are crucial.Q: When should I choose polyurethane liners for my equipment?

A: Opt for these liners when your application demands high wear resistance, flexibility, and reliable performance under variable temperatures and impact risks, especially in heavy-duty or high-throughput environments.Q: What is the standard thickness range for these liners?

A: The standard available thickness ranges from 2 mm to 100 mm, allowing customization based on wear protection requirements and installation constraints.Q: How does the smooth surface finish contribute to performance?

A: The smooth surface prevents material buildup and promotes easy flow, reducing cleaning frequency and enhancing productivity in material transport applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

Polyurethane Hydrocyclone

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Purity : Other, 99%

Form : Other, Cylindrical/Conical

Grade : Industrial Grade

Size : Customizable size as per application

Industrial Polyurethane Strips

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Purity : Other, 99%

Form : Other, Strip

Grade : Industrial Grade

Size : Customizable (Width: 10200 mm, Thickness: 230 mm, Length: on demand)

Polyurethane Bushes

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Purity : Other, High Purity

Form : Other, Solid / Molded

Grade : Industrial Grade

Size : Customizable

Conveyors Rollers

Minimum Order Quantity : 1 Piece

Purity : 96%

Form : Solid

Grade : Industrial Grade

Size : As per Customer Reguirement

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry