|

Polyurethane Hydrocyclone

Polyurethane Hydrocyclone Specification

- Classification

- Polyurethane Hydrocyclone

- Type

- Hydrocyclone Separator

- CAS No

- 9009-54-5

- EINECS No

- 618-498-9

- Grade

- Industrial Grade

- Purity

- 99%

- Application

- Color

- Yellow

- Form

- Cylindrical/Conical

- Size

- Customizable size as per application

- Material

- Polyurethane

- Inner Diameter

- 10 mm - 500 mm (as per requirement)

- Abrasion Resistance

- High

- Feature

- Lightweight, easy to install and maintain

- Working Pressure

- 0.2 - 2.5 MPa

- Service Life

- Up to 3 times longer than rubber liners

- Temperature Resistance

- -30°C to 80°C

- Corrosion Resistance

- Excellent

- Hardness

- Shore Hardness 85-95 A

- Flow Rate Capacity

- Up to 1000 m3/h (depending on size)

- Installation

- Flange or clamp connection

Polyurethane Hydrocyclone Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Polyurethane Hydrocyclone

With firm commitment to quality, we are involved in manufacturing and supplying a wide range of Polyurethane Hydrocyclone. The offered product is widely used in mining and quarry industries for separating heavies from the mixture of liquid. It is manufactured under the stern guidance of our deft professionals by utilizing excellent quality polyurethane with the aid of modern techniques. Further, the provided Polyurethane Hydrocyclone is available in different dimensions as per the exact requirements of the clients at marginal rates.

Features:

- Rugged design

- High durability

- Excellent finish

- Easy installation

Precision Separation for Challenging Industrial Processes

Designed to handle robust industrial applications, the Polyurethane Hydrocyclone provides effective separation of solids and liquids across mining, mineral processing, sand washing, and chemical industries. Its customizable sizing and durable material make it highly adaptable to site-specific requirements, ensuring optimal performance regardless of scale or complexity.

Engineered Strength and Longevity

With Shore Hardness of 85-95 A and a service life up to three times longer than traditional rubber liners, this hydrocyclone showcases exceptional durability. Its high resistance to abrasion and corrosion allows it to perform reliably under extremes of pressure and temperature, minimizing downtime and reducing maintenance costs.

Simple Installation and Ease of Maintenance

Installation is straightforward, using either flange or clamp connections to fit seamlessly into existing systems. Its lightweight construction not only streamlines setup but also simplifies routine maintenance, contributing to reduced operational interruptions and greater overall efficiency.

FAQs of Polyurethane Hydrocyclone:

Q: How does the Polyurethane Hydrocyclone function in solid-liquid separation?

A: The Polyurethane Hydrocyclone uses centrifugal force to efficiently separate solids from liquids, directing the heavier solid particles toward the wall and out through the underflow, while cleaned liquid exits through the overflow. This process is essential for industries needing precise mineral, sand, or chemical separation.Q: What benefits does polyurethane offer compared to traditional rubber liners?

A: Polyurethane provides excellent abrasion and corrosion resistance, resulting in a hydrocyclone that lasts up to three times longer than those with rubber liners. Its toughness and flexibility enable it to withstand higher pressures and harsher conditions, lowering replacement frequency and reducing maintenance costs.Q: When is it best to choose the Polyurethane Hydrocyclone for industrial use?

A: This hydrocyclone is ideal when applications demand frequent or severe separation cycles, require resistance to aggressive chemicals or abrasive materials, and need prolonged service life with minimal downtime. Its particularly advantageous in mining, mineral processing, and sand washing operations.Q: Where can the Polyurethane Hydrocyclone be installed?

A: It can be installed at any stage within separation circuits in mining, sand washing, chemical plants, and mineral processing facilities. Its flange or clamp connection options allow for easy integration into both new and existing pipelines or equipment setups.Q: How is the installation of the hydrocyclone carried out?

A: Installation involves positioning the hydrocyclone within the desired section of the separation system and securing it using either flange or clamp connections. Its lightweight design makes it easy to handle, while customizable sizing ensures compatibility with various pipe diameters.Q: What is the typical process for maintaining the Polyurethane Hydrocyclone?

A: Routine maintenance primarily involves visual inspections for wear and periodic cleaning to prevent blockages. The rugged polyurethane construction significantly reduces the frequency of part replacements, simplifying upkeep and avoiding operational disruptions.Q: What operational advantages does this hydrocyclone provide?

A: It delivers reliable separation efficiency, handles a broad range of pressures and temperatures, and supports flow capacities up to 1000 m3/h, depending on the size. The hydrocyclones lightweight structure, ease of installation, and extended lifespan contribute to lower total ownership costs and enhanced industrial productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

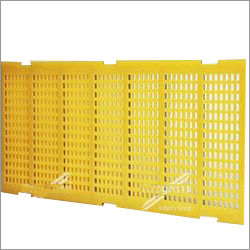

Modular Polyurethane Screen Panels

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Polyurethane (PU)

Form : Other, Panel

Grade : Industrial Grade

Color : Other, Yellow or Customized

Polyurethane Bushes

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Polyurethane

Form : Other, Solid / Molded

Grade : Industrial Grade

Color : Yellow

Polyurethane Gear Couplings

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Polyurethane & Steel

Form : Solid

Grade : Industrial Grade

Color : Yellow

PU Tiles

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : PU

Form : Solid

Grade : Industrial Grade

Color : Multicolored

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry