|

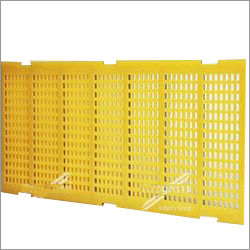

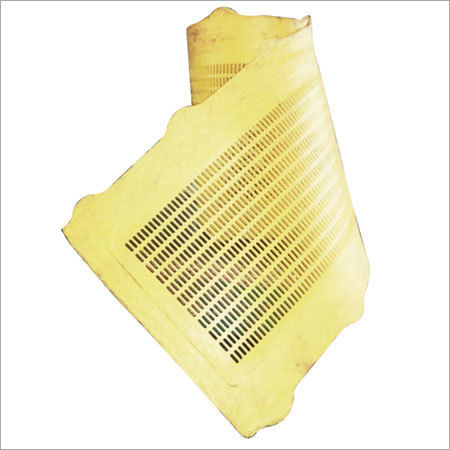

Modular Polyurethane Screen Panels

Modular Polyurethane Screen Panels Specification

- Classification

- Polyurethane Screen Panel

- Type

- Modular

- CAS No

- 9009-54-5

- EINECS No

- 618-483-1

- Grade

- Industrial Grade

- Purity

- High Purity

- Application

- Mining, Quarrying, Aggregate Screening, Coal Washing Plants

- Color

- Yellow or Customized

- Form

- Panel

- Size

- 300mm x 300mm; Customizable sizes available

- Material

- Polyurethane (PU)

- Abrasion Resistance

- Excellent

- Operating Temperature

- -35°C to +80°C

- Weight

- Lightweight design for easy handling

- Usage

- Wet and dry screening applications

- Open Area Percentage

- Up to 50%

- Screening Efficiency

- High

- Noise Reduction

- Significant compared to metal screens

- Hardness

- 80-95 Shore A

- Maintenance

- Easy replacement and low maintenance

- Installation

- Modular fastening system

- Service Life

- Extended compared to traditional screens

- Moisture Absorption

- Low

- Aperture Size

- 0.3mm to 100mm (customized available)

- Impact Resistance

- Superior

Modular Polyurethane Screen Panels Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Modular Polyurethane Screen Panels

Modular Polyurethane Screen Panels

Owing to our in-depth expertise in this domain, we are engaged in manufacturing and supplying versatile Modular Polyurethane Screen Panels that has high operational fluency. The screen provided by us is used in various applications like steel plants, mining industry, cement plants and power plants. Under our adroit professionals' guidance, this screen is manufactured with the finest quality raw materials like polyurethane and the progressive technology. As per the variegated requirement of the clients, we provide this Modular Polyurethane Screen Panels in different specifications at industry leading rates.

Features:

- Sturdiness

- Optimum strength

- Longer service life

- High durability

Optimized Screening Performance

Polyurethane screen panels deliver high screening efficiency and up to 50% open area, allowing for faster material throughput and increased productivity in both wet and dry environments. The modular design enhances adaptability for diverse applications, including mining, quarrying, and aggregate screening, ensuring precise particle separation and improved operational output.

Superior Durability and Lasting Value

With exceptional abrasion and impact resistance, these panels ensure extended service life compared to traditional metal screens. Their robust polyurethane composition supports continuous operation under harsh conditions while reducing downtime and replacement costs. Low moisture absorption further enhances panel longevity and performance stability.

Simplified Maintenance and Installation

The modular fastening system enables fast and easy panel replacement, minimizing maintenance intervals. Lightweight design allows for effortless handling and installation, making these panels a practical choice for facilities seeking to optimize efficiency and reduce labor requirements. Significant noise reduction during screening also improves overall workplace safety and comfort.

FAQs of Modular Polyurethane Screen Panels:

Q: How are modular polyurethane screen panels installed in screening equipment?

A: These panels utilize a modular fastening system, allowing for simple and secure installation. The modular design enables easy panel replacement and quick adjustments to fit specific screening equipment, minimizing downtime and enhancing operational flexibility.Q: What applications can these polyurethane screen panels be used for?

A: They are ideally suited for mining, quarrying, aggregate screening, coal washing plants, and other mineral processing operations. Their robust properties make them effective in both wet and dry screening environments.Q: When should I consider switching to polyurethane screen panels from traditional metal screens?

A: Switching is recommended when seeking extended service life, higher screening efficiency, reduced maintenance costs, and significant noise reduction in your operation. Polyurethane panels outperform metal screens in impact resistance and abrasion durability.Q: Where are these panels manufactured and supplied from?

A: As an exporter, manufacturer, and supplier based in India, these polyurethane panels are produced using high purity materials with customizable sizes and apertures to meet global industry standards.Q: What is the process for customizing aperture sizes and panel dimensions?

A: Customization is available for aperture sizes (0.3mm to 100mm) and panel dimensions. The process involves specifying required sizes and features during order placement, enabling precise tailoring for unique screening needs.Q: Why do these panels offer significant noise reduction compared to metal screens?

A: Made from polyurethane, the panels absorb vibration and sound, substantially lowering operational noise. This feature creates a safer, more comfortable work environment while maintaining high screening performance.Q: What are the key benefits of using modular polyurethane screen panels?

A: Users benefit from high screening efficiency, superior abrasion and impact resistance, extended lifespan, low moisture absorption, easy maintenance, lightweight handling, and customizable featuresmaking these panels a versatile and cost-effective choice for industrial screening.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

Polyurethane Liners

Minimum Order Quantity : 1 Piece

Grade : Industrial Grade

Classification : Other, Polymers

Form : Other, Sheet / Plate / Liner

Application : Other, Wear Resistance, Abrasion Protection, Material Handling, Mining Industry, Chute Lining, Hopper Lining, Conveyor Systems

Polyurethane Bushes

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Industrial Grade

Classification : Other, Polyurethane Elastomer

Form : Other, Solid / Molded

Application : Other, Automotive, Mechanical Engineering, Industrial Machinery

Polyurethane Chuted Liner

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Industrial Grade

Classification : Other, Polyurethane Product

Form : Other, Sheet/Panel

Application : Other, Chute lining for abrasionresistant applications in mining, material handling, and bulk conveying systems

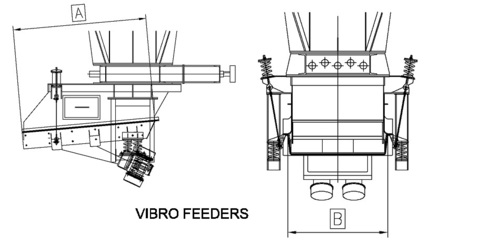

Polyurethane Vibro Feeders

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Other, Premium

Classification : Other, Industrial Component

Form : Solid

Application : Other, Material Handling, Controlled Feeding, Manufacturing Automation

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry