|

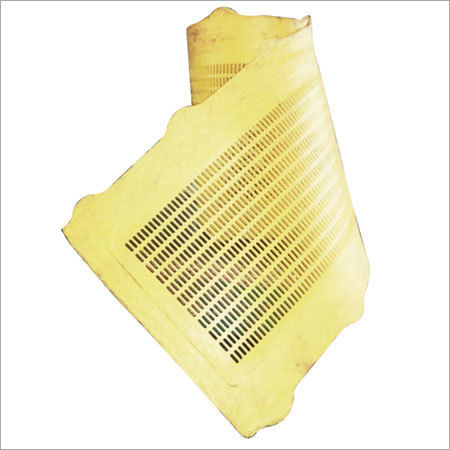

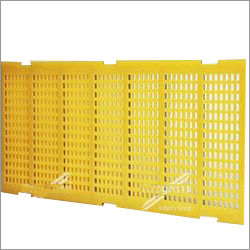

Polyurethane Flip Flow Screen Mats

Price 7000 INR/ Piece

Polyurethane Flip Flow Screen Mats Specification

- Classification

- Screening Media

- Type

- Polyurethane Flip Flow Screen Mats

- Grade

- Industrial

- Purity

- High

- Application

- Vibration Screen Machines, Mineral Screening

- Color

- Yellow, Red, Custom

- Form

- Rectangular Mats

- Size

- Customizable as per machine design

- Material

- Polyurethane

- Tensile Strength

- Excellent

- Thickness

- 5 mm to 25 mm

- Hole Type

- Square, Slotted, Round, Custom

- Customizability

- Shape, size, thickness, and color customizable

- Chemical Resistance

- Resistant to oil, solvents, and most chemicals

- Installation Type

- Bolt/Clamp Supported

- Wear Resistance

- High

- Life Span

- Extensive, up to 3 times longer than traditional screens

- Hardness

- 65-90 Shore A

- Operating Temperature Range

- -40°C to +80°C

- Mesh Opening Size

- 0.5 mm to 50 mm

- Surface Finish

- Smooth/Glossy

Polyurethane Flip Flow Screen Mats Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Polyurethane Flip Flow Screen Mats

Polyurethane Flip Flow Screen Mats

We are recognized as the prominent manufacturer and supplier of wide collection of Polyurethane Flip Flow Screen Mats that is used for the screening of the humid materials. The offered screen is precisely manufactured by our deft professionals using the optimum quality raw materials in conformity with the set industry norms. Widely used in various industries like automobile, chemical, construction and many more this screen is known for its optimum strength and high durability. Moreover, the offered Polyurethane Flip Flow Screen Mats/Polyurethane Screen Mats is available with us in shapes, sizes and finishes as per the requirements of the clients.

Products Features:

- Excellent finish

- Easy to install

- Weather resistance

- Durability

Unmatched Durability and Performance

Our Polyurethane Flip Flow Screen Mats offer exceptional wear resistance and tensile strength, making them suitable for rigorous industrial screening tasks. Operating seamlessly in both low and high-temperature environments, they maintain stability and efficiency even during extended use. This results in increased productivity and reduced maintenance costs due to their significant lifespan advantage over traditional screens.

Precision Engineering and Customization

Each screen mat can be tailored in terms of size, shape, thickness, mesh opening, and color to perfectly fit your unique screening machine requirements. Multiple hole typessquare, slotted, round, or customensure optimal material handling and classification. The smooth and glossy surface finish enhances the screening process, minimizing material build-up and maximizing throughput.

Chemical and Oil Resistance

Constructed from high-purity polyurethane, these mats demonstrate strong resistance to oil, solvents, and various chemicals often found in mineral screening and processing industries. This resilience ensures consistent performance and longer service intervals in harsh chemical environments, making them an ideal choice for industries requiring robust and reliable screening solutions.

FAQs of Polyurethane Flip Flow Screen Mats:

Q: How should Polyurethane Flip Flow Screen Mats be installed?

A: These mats can be installed using either bolt or clamp support systems, depending on your screening equipments design. Installation is straightforward, and customized sizes ensure a precise fit for effective operation.Q: What customization options are available for these screen mats?

A: Customers can specify the shape, size, thickness, mesh opening size, hole type, surface finish, and color, allowing the screen mats to be tailored for a range of applications and machine designs.Q: When is it most beneficial to use polyurethane mats instead of metal screens?

A: Polyurethane mats are ideal when extended service life, superior wear resistance, chemical resistance, and quieter operation are desiredespecially in mineral screening or environments with abrasive or corrosive materials.Q: Where can these screen mats be utilized?

A: They are widely applicable in vibration screen machines, mineral screening operations, and many other industrial processes requiring reliable material separation. As a major exporter and manufacturer from India, we provide mats suitable for both local and international markets.Q: What is the process for ordering custom-sized screen mats?

A: You need to provide your machines design specifications, including required dimensions, mesh opening size, and desired material characteristics. Our team will then engineer and manufacture mats to your precise requirements.Q: How do these mats benefit operational efficiency?

A: With a lifespan up to three times longer than conventional screens, reduced maintenance frequency, and exceptional resistance to wear and chemicals, these mats deliver significant cost savings and operational continuity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry