|

New Polyurethane Hydrocyclone

New Polyurethane Hydrocyclone Specification

- Classification

- Hydrocyclone Equipment

- Type

- Polyurethane Hydrocyclone

- Grade

- Industrial

- Purity

- High

- Application

- Solid-liquid separation, Mining, Mineral Processing

- Color

- Yellow

- Form

- Molded

- Material

- Polyurethane

- Size

- Customizable (typically 10mm to 500mm diameter)

- Pressure Range

- 0.2MPa - 0.6MPa

- Wear Resistance

- Excellent, suitable for abrasive slurries

- Flow Capacity

- 10 1000 m/h (varies by size)

- Wall Thickness

- Optimized for high pressure and durability

- Feature

- Corrosion and abrasion resistant, lightweight, easy installation

- Service Life

- Long, up to 3x longer than conventional types

- Operating Temperature

- -20C to +80C

- Connection Type

- Flanged or clamped

New Polyurethane Hydrocyclone Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 1 Week

About New Polyurethane Hydrocyclone

Owing to our expertise, we are manufacturing and supplying a wide gamut of Polyurethane Hydrocyclone. The offered cyclone is manufactured by our adept team of professionals using supreme grade polyurethane with the aid of progressive technology. This cyclone is exclusively used in fire stations to maintain the water flow. Also, tested on various quality parameters, the provided cyclone is available in various specifications. Our precious clients can avail the offered Polyurethane Hydrocyclone at reasonable prices from us.

Features:

- Excellent durability

- Easy to fit

- High strength

- Precisely engineered

Superior Durability with Advanced Polyurethane

Manufactured from high-purity, molded polyurethane, this hydrocyclone provides outstanding abrasion and corrosion resistance. The optimized wall thickness ensures excellent performance and longevity, even under high pressure and with rigorous slurry applications. Its durable structure significantly reduces maintenance and replacement costs.

Optimized Performance for Mining and Mineral Processing

Engineered for solid-liquid separation, the hydrocyclone offers high efficiency in mining and mineral processing operations. With customizable diameters and adjustable flow capacities, it adapts perfectly to diverse industrial requirements, ensuring reliable results and consistent throughput, regardless of the complexity of the slurry handled.

Effortless Installation and Versatile Connections

Designed for user convenience, the hydrocyclone features lightweight construction and a choice of flanged or clamped connections. This flexibility simplifies setup, minimizes downtime, and ensures easy integration into existing pipeline systems, whether for new installations or upgrades.

FAQs of New Polyurethane Hydrocyclone:

Q: How is the Polyurethane Hydrocyclone installed in industrial settings?

A: The hydrocyclone is designed for easy installation with either flanged or clamped connection types, allowing straightforward integration into existing slurry pipelines and processing systems.Q: What advantages does the polyurethane construction provide for abrasive slurry applications?

A: Polyurethane offers excellent wear resistance and durability, significantly extending service life and providing high performance against corrosive and abrasive slurries encountered in mining and mineral processing.Q: When should I choose a customized hydrocyclone size?

A: Customization is recommended when your flow capacity requirements, particle size distribution, or pipeline dimensions do not align with standard sizes. Sizes typically range from 10mm to 500mm diameter, catering to various operational needs.Q: Where is this hydrocyclone typically used?

A: This hydrocyclone is primarily used in mining, mineral processing, and other industrial applications involving solid-liquid separation, especially where abrasive materials are present.Q: What is the process for solid-liquid separation using this equipment?

A: A slurry enters the hydrocyclone under pressure, where centrifugal forces cause solid particles to separate from the liquid. The solids are discharged from the underflow, while the cleaned liquid exits through the overflow.Q: What benefits does the enhanced wall thickness provide?

A: The optimized wall thickness improves the hydrocyclones capacity to withstand high pressures and abrasive materials, increasing durability and providing up to three times longer service life compared to conventional models.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

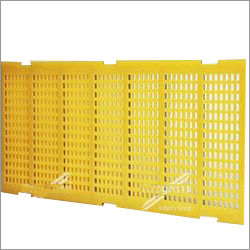

PU Products

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Material : Polyurethane (PU)

Application : Other, Automotive, Industrial Machinery, Construction, Textile and Footwear Industries

Form : Other, Solid / Moulded Form

Polyurethane Expansion Joints

Minimum Order Quantity : 1 Piece

Color : Yellow

Material : Polyurethane

Application : Other, Bridge, Construction, Roadways, Industrial Flooring

Form : Other, Molded/Sheet

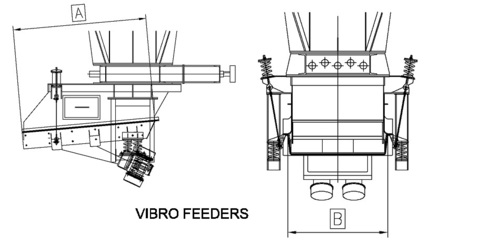

Polyurethane Vibro Feeders

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Material : Polyurethane

Application : Other, Material Handling, Controlled Feeding, Manufacturing Automation

Form : Solid

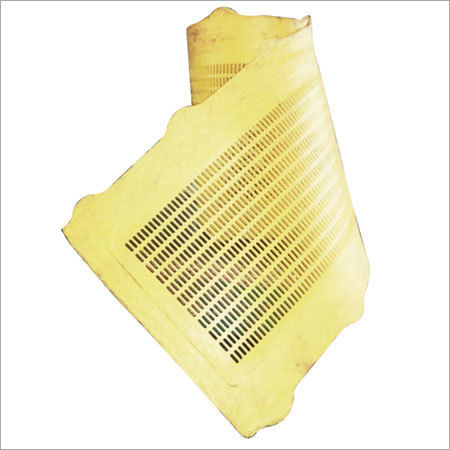

Polyurethane Liner

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Multicolored

Material : PU

Application : Other, Used To Protect Metal Hoppers And Chutes From Abrasive Compounds

Form : Solid

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry