|

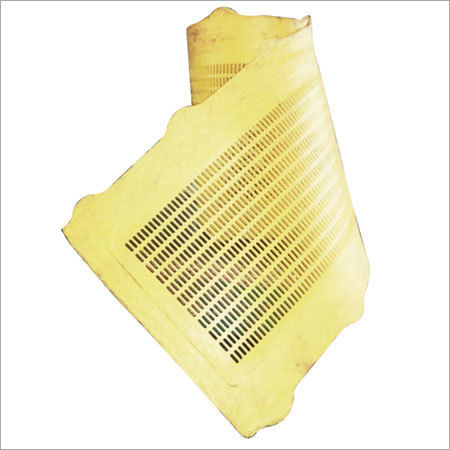

Polyurethane Chuted Liner

Polyurethane Chuted Liner Specification

- Classification

- Polyurethane Product

- Type

- Chuted Liner

- CAS No

- 9009-54-5

- EINECS No

- 618-498-9

- Grade

- Industrial Grade

- Purity

- 99%

- Application

- Chute lining for abrasion-resistant applications in mining, material handling, and bulk conveying systems

- Color

- Red

- Form

- Sheet/Panel

- Size

- Customized, as per requirement

- Material

- Polyurethane

Polyurethane Chuted Liner Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Polyurethane Chuted Liner

We are engaged in manufacturing and supplying a high quality range ofPolyurethane Chuted Liner.These are made using quality material procured from reliable vendors of repute. Our extensive range of supply Hopper liners is much appreciated by the clients for its optimum performance and quality.Superior Abrasion Resistance for Heavy-Duty Operations

Polyurethane Chuted Liners are specifically designed to withstand extreme abrasion and wear in high-impact working conditions. Their robust construction ensures minimal downtime in mining and material handling facilities, extending the operational life of chutes and related equipment even under intense, continuous use.

Customizable and Easy to Install Solutions

These liners are produced in various thicknesses and sizes, tailored to fit your specific requirement. Installation is simple, either by bolting on or using adhesive mounting offering flexibility during upgrades or maintenance, without significant modifications to existing chute structures.

Enhanced Safety and Performance

With excellent noise reduction and non-corrosive features, Polyurethane Chuted Liners contribute to a safer, more efficient workplace. The smooth or matte finish also helps in preventing material build-up, ensuring smoother material flow and reducing the likelihood of blockages in your conveying systems.

FAQs of Polyurethane Chuted Liner:

Q: How are Polyurethane Chuted Liners installed in existing chute systems?

A: Polyurethane Chuted Liners can be fitted using either bolt-on methods or strong industrial adhesives, providing flexibility based on your chute construction and operational needs. This facilitates quick installation and maintenance while minimizing equipment downtime.Q: What benefits do these liners offer compared to traditional steel or rubber liners?

A: These liners outperform steel or rubber counterparts by delivering superior abrasion and wear resistance, enhanced impact tolerance, significant noise reduction, and total non-corrosiveness. They also minimize maintenance requirements and promote longer service life in harsh environments.Q: When should I choose a Polyurethane Chuted Liner for my application?

A: A Polyurethane Chuted Liner is highly recommended for situations demanding excellent resistance to abrasion and impact, especially in mining, material handling, or bulk conveying applications that operate under heavy-duty conditions and require extended service intervals.Q: Where can Polyurethane Chuted Liners be used most effectively?

A: These liners are most effective in high-wear zones within mining chutes, transfer points, silos, and other bulk material handling equipment, where abrasive flow and heavy impacts are common. Their versatility allows use in a wide variety of industrial sectors.Q: What is the typical process for customizing these liners to fit specific requirements?

A: Customization involves providing detailed size and thickness specifications. The manufacturer will then fabricate the liners as per your requirements, ensuring a perfect fit and optimal performance in your particular application.Q: How do these liners contribute to noise reduction in conveying systems?

A: The viscoelastic properties of polyurethane absorb vibration and sound, making these liners highly effective at dampening noise generated by material flow or impact within chutes and conveyors, improving worksite comfort and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

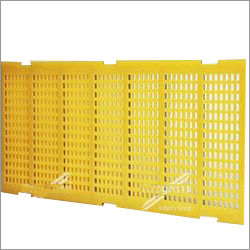

Modular Polyurethane Screen Panels

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Polyurethane (PU)

Color : Other, Yellow or Customized

Form : Other, Panel

Size : 300mm x 300mm; Customizable sizes available

Polyurethane Hydrocyclone

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Polyurethane

Color : Yellow

Form : Other, Cylindrical/Conical

Size : Customizable size as per application

Pu Rock Breaker Damper Pad

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Polyurethane (PU)

Color : Yellow

Form : Solid

Size : Customizable

Polyurethane Liner

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : PU

Color : Multicolored

Form : Solid

Size : As per Customer Reguirement

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry