|

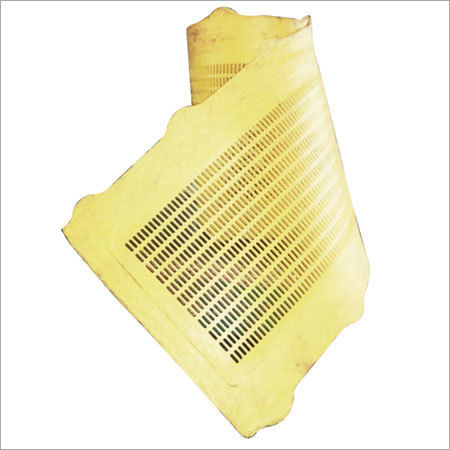

Fine Mesh Dewatering Screen

Price 1000 INR/ Piece

Fine Mesh Dewatering Screen Specification

- Classification

- Dewatering Equipment

- Type

- Fine Mesh Screen

- Grade

- Industrial

- Application

- Solid-liquid separation, Mining, Sand washing, Wastewater treatment

- Color

- Gray/Silver

- Form

- Screen Mesh

- Size

- Customizable

- Material

- Stainless Steel/Steel

Fine Mesh Dewatering Screen Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

About Fine Mesh Dewatering Screen

Vibration Screeningis used in order to separate the various kinds of materials into different sizes for the purpose of further processing them. These screens work to remove the impurities like plastics, metal particles, wooden splinters and so on. In this the material is made to pass through the vibrating screen box and it can be dropped to the conveyors which are attached to the box. These screens are famous for their ability to separate the accuracy which is required for the purpose of bulk manufacturing the products.

Features

- Durable

- Robust build

- Reliable

Versatile Fine Mesh Design

The fine mesh dewatering screen provides superior solid-liquid separation due to its customizable mesh size and robust construction. Choose from various micron ratings with screen thickness adjustable between 2 and 10 mm, tailored to suit specific application requirements. The anti-corrosive, polished finish ensures reliable operation in harsh environments.

High Performance Across Industries

This screen demonstrates excellent performance in mining, quarrying, chemical processing, power plants, and wastewater treatment. Its high throughput capacity and minimal clogging design make it ideal for heavy-duty industrial operations. Operating efficiently at temperatures up to 200C, it meets the demands of challenging solid-liquid separation tasks.

Custom Solutions and Easy Installation

Delivered in custom shapes and sizes, the dewatering screen can be easily installed via bolt-on or fixed mounting. As an exporter, manufacturer, and supplier based in India, we support custom engineering to meet client specifications. The robust build ensures a long service life, reducing downtime and maintenance costs.

FAQs of Fine Mesh Dewatering Screen:

Q: How is the Fine Mesh Dewatering Screen installed in existing systems?

A: Installation is straightforward, as the screen can be mounted using either a bolt-on or fixed mounting approach. Custom shapes and sizes are available to integrate seamlessly with new or pre-existing systems, and installation guidance or support can be provided as needed.Q: What industries can benefit from using this Fine Mesh Dewatering Screen?

A: This screen is highly beneficial for mining, quarrying, chemical manufacturing, power generation, sand washing, and wastewater treatment. Its durable, anti-corrosive design and customizable features make it suitable for a broad range of industrial solid-liquid separation needs.Q: When should I consider a custom mesh size or screen opening for my application?

A: Custom mesh sizes or screen openings should be selected when standard options do not meet your required separation efficiency or particle retention criteria. Customization ensures optimal dewatering performance and is especially important for unique or demanding industrial processes.Q: Where are these screens typically used within a facility?

A: These screens are typically found at the point of solid-liquid separationsuch as discharge points in dewatering lines, sand washing installations, or wastewater treatment bays. Their robust design allows deployment wherever fine and reliable separation is vital.Q: What process advantages does this screen offer over traditional dewatering equipment?

A: The fine mesh screen offers superior dewatering efficiency, high throughput, reduced risk of clogging, and a longer working lifespan. Its polished, anti-corrosive surface minimizes maintenance while ensuring effective operation even with highly abrasive or chemically aggressive materials.Q: How does the surface treatment enhance screen performance?

A: The anti-corrosive and polished surface treatment protects the screen from rust and chemical deterioration, especially important in harsh industrial settings. This increases the screens operational reliability and extends its service life, minimizing unscheduled downtime.Q: What are the main benefits of choosing a customizable Fine Mesh Dewatering Screen?

A: By opting for a customizable solution, users can specify mesh size, screen thickness, shape, and mounting style to perfectly fit their process requirements. This tailored approach maximizes separation efficiency, ensures compatibility, and promotes safer, more reliable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

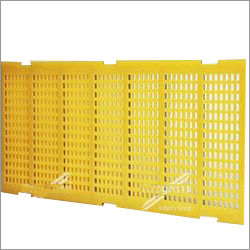

More Products in Polyurethane Screens Category

Modular Polyurethane Dewatering Screen

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Other, Industrial

Application : Other, Dewatering, Mining, Sand Processing, Aggregate Screening

Type : Other, Dewatering Screen Panel

Classification : Other, Screen Mesh

|

JOYTECH POLYURETHANE WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry